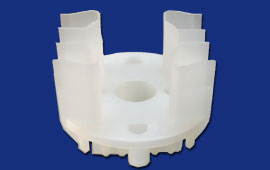

Injection Moulding

GPI's expertise lies in production of close-tolerance functional parts from high performance engineering polymers.

GPI's expertise lies in production of close-tolerance functional parts from high performance engineering polymers.

Our parts need to undergo validating testing so as to test their endurance under sustained load conditions. GPI possess 40+ years of experience in establishing such processes and by employing the techniques of Scientific Molding, we are able to optimize process parameters to correct inconsistencies, ensure repeatability, and maximize efficiency. In addition to the complete range of conventional engineering polymers, we have experience with the more exotic materials such as those based on high temperature resistant polymers and those with performance enhancing additives.

We process PPS, PES, PA 4.6, PA 6.6, PA 6, PBT, POM, PC, Alloys, TPU, TPE etc. Materials with fillers such as Short Glass Fibre, Long Glass FIbre, Glass Beads, PTFE, Aramid Fibre, Conductive Fillers, Carbon, MoS2 and various Mineral Fillers are used. We resort to post moulding processes and specialised fixtures to control the dimensions of the product.