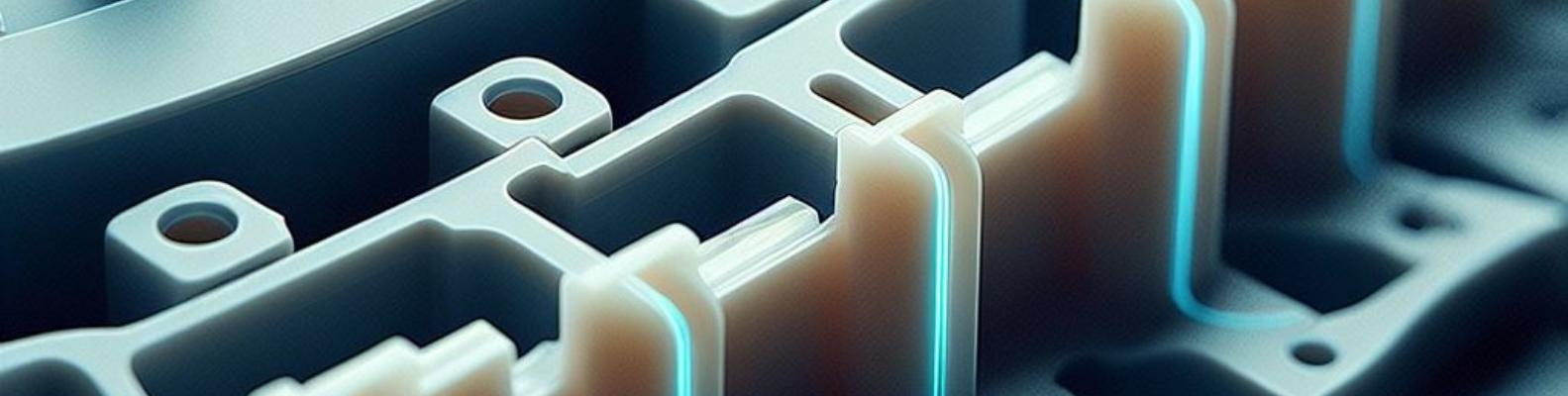

Injection molding is a widely used manufacturing process for producing parts by injecting molten material into a mold. This process is utilized for making a variety of plastic products, from everyday household items to intricate components used in the automotive and electronics industries. A crucial aspect of the injection molding process is the mold design, and an essential feature of this design is the parting line.

Definition of a Parting Line

The parting line in injection molding is the line or surface where the two halves of the mold meet. When the mold closes, the molten plastic is injected into the cavity, filling the shape of the desired part. Once the plastic cools and solidifies, the mold opens, allowing the finished part to be ejected. The line or area where the mold halves separate and meet is known as the parting line.

Importance of the Parting Line

The parting line is critical in injection molding for several reasons:

1. Aesthetic Quality: The parting line often leaves a visible seam on the final product. While this can be minimized, it cannot be entirely eliminated. For products where appearance is crucial, the placement and treatment of the parting line must be carefully considered to ensure it does not detract from the overall look.

2. Functional Integrity: A poorly designed parting line can affect the functionality of the part. If the parting line is not aligned correctly, it can result in flash, where excess plastic seeps out between the mold halves. This excess material must be trimmed off, which adds an extra step to the production process and can affect the precision of the part.

3. Ease of Manufacture: The parting line impacts the ease with which the part can be manufactured and removed from the mold. Proper placement ensures that the part can be easily ejected without damaging it or the mold.

4. Structural Strength: The location of the parting line can influence the strength and durability of the part. Certain designs may require the parting line to be placed in a way that avoids critical areas of the part that bear significant loads or stress.

Factors Influencing Parting Line Placement

Several factors influence where the parting line is placed on a part:

1. Part Geometry: The shape and complexity of the part largely determine the most appropriate location for the parting line. Complex parts may require more strategic placement to ensure moldability and part integrity.

2. Mold Design: The design of the mold itself, including considerations like the number of cavities, gate locations, and ejection mechanisms, affects parting line placement.

3. Draft Angles: Parts with draft angles (sloped surfaces that allow for easier removal from the mold) need careful parting line placement to ensure the part can be ejected without sticking.

4. Aesthetic Considerations: For parts where appearance is important, the parting line may be placed in less visible areas or designed in a way that makes the seam less noticeable.

5. Material Flow: The way molten plastic flows into the mold can impact the parting line. Uniform flow can help minimize defects and ensure consistent part quality.

Types of Parting Lines

There are several types of parting lines, each suited for different types of parts and mold designs:

1. Straight Parting Line: The simplest type, where the parting line follows a straight path around the part. This is often used for simple, symmetrical parts.

2. Stepped Parting Line: Used for parts with varying heights or multiple levels, the parting line follows a stepped path. This allows for better alignment and reduces the risk of flash.

3. Curved Parting Line: For more complex parts, a curved parting line may be used. This can follow the contours of the part and is often used to maintain aesthetic quality.

Challenges and Solutions

Designing the parting line presents several challenges, but there are solutions to address them:

1. Flash: Flash occurs when molten plastic seeps between the mold halves. This can be minimized by ensuring the mold halves fit tightly together and by optimizing the clamping force.

2. Alignment Issues: Misalignment of the mold halves can lead to defects. Precision machining and regular maintenance of the mold can help ensure proper alignment.

3. Parting Line Visibility: For parts where appearance is critical, secondary operations like trimming, sanding, or polishing can reduce the visibility of the parting line. Alternatively, the parting line can be designed to follow natural lines in the part’s design, making it less noticeable.

4. Wear and Tear: The parting line is subject to wear and tear due to repeated opening and closing of the mold. Using durable materials and regular maintenance can extend the life of the mold.

Conclusion

The parting line in injection molding is a fundamental aspect of mold design and manufacturing. Its placement affects the aesthetic quality, functional integrity, ease of manufacture, and structural strength of the final product. By carefully considering factors such as part geometry, mold design, draft angles, aesthetic considerations, and material flow, manufacturers can optimize the placement of the parting line to produce high-quality parts efficiently. Despite the challenges associated with parting line design, employing best practices and regular maintenance can mitigate issues and ensure the longevity and performance of the mold.