Plastic components play a crucial role across various industries, including automotive, home appliances, and medical devices. These components, made from a variety of plastics, are essential for protecting, enhancing, and constructing a wide array of products.

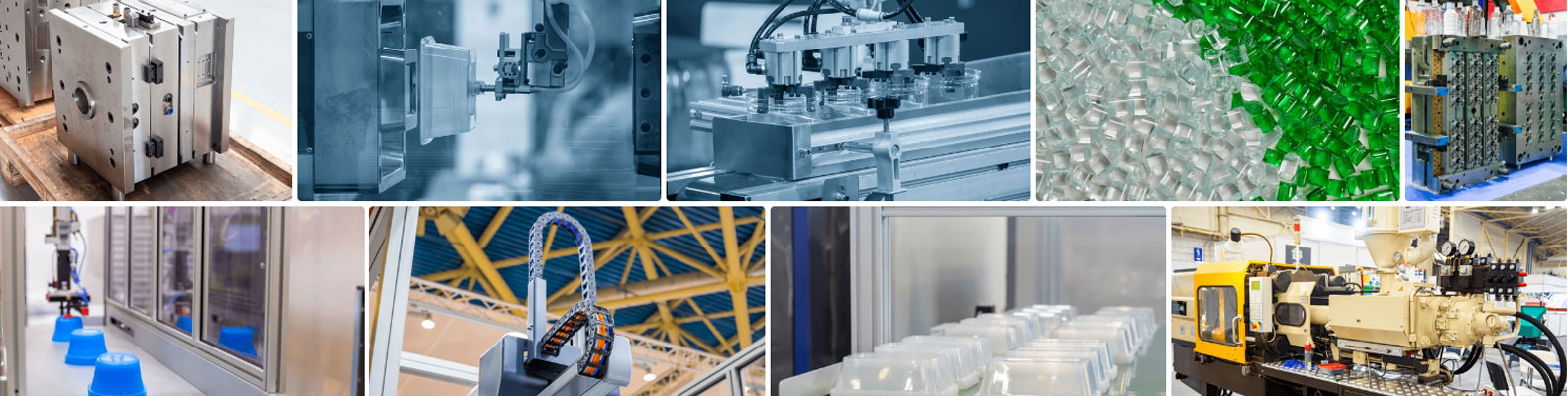

Injection molding is one of the most widely used methods for producing these plastic components, known for its dependable and high-quality output. The injection molded plastics market is expected to grow at a compound annual growth rate (CAGR) of 4.6% through 2028, reflecting the process's importance and widespread use.

However, despite its efficiency in producing large quantities of plastic components rapidly, the injection molding process requires precise control to ensure the final parts meet high-quality standards. In this article, we'll explore how injection molding works and how skilled manufacturers manage the process to deliver top-quality plastic components. We'll cover:

The Basics of Plastic Injection Molding

The plastic injection molding procedure consists of key stages: clamping, injecting, cooling, and ejecting. Each stage plays a critical role in ensuring the final product meets the required specifications.

Clamping:

The process begins with the clamping stage, where the two halves of the mold are securely closed. The mold is typically made from steel or aluminum and is designed to match the precise dimensions of the part being produced. The clamping unit, which is part of the injection molding machine, holds the mold in place with significant force to prevent any leakage of the molten plastic during the injection phase. The clamping force is precisely determined according to the size and complexity of the part, along with the specific material being used.

Injection:

Once the mold is clamped shut, the injection stage begins. In this stage, plastic pellets or granules are fed into a heated barrel, where they are melted by a combination of heat and pressure. The molten plastic is then injected into the mold cavity through a nozzle at high pressure. The injection pressure must be precisely controlled to ensure the material flows into all areas of the mold, filling every nook and cranny. The speed and pressure of the injection process are critical factors that influence the quality of the final part, affecting properties such as strength, surface finish, and dimensional accuracy.

Cooling:

After the molten plastic has filled the mold cavity, it begins to cool and solidify. The cooling stage is crucial as it determines the final shape and mechanical properties of the part. The mold is typically equipped with cooling channels that allow water or other cooling fluids to circulate, helping to regulate the temperature and speed up the cooling process. The cooling time can vary depending on the type of plastic used, the thickness of the part, and the complexity of the mold. Proper cooling is essential to avoid defects such as warping, sink marks, or internal stresses.Ejection:

Once the part has sufficiently cooled and solidified, it is ready to be removed from the mold. The ejection stage involves opening the mold and using an ejection system, usually consisting of pins or plates, to push the part out of the mold cavity. The mold is then prepared for the next cycle, and the process begins again. Ejection must be done carefully to prevent damage to the part, especially if the part has complex or delicate features.Materials Used in Plastic Injection Molding

A wide range of plastic materials can be used in injection molding, each offering different properties that make them suitable for specific applications. Here are some commonly used materials:Polyethylene (PE): Known for its durability and flexibility, polyethylene is widely used in packaging, consumer goods, and automotive parts.

Polypropylene (PP): This material is known for its chemical resistance and is commonly used in automotive components, medical devices, and food containers.

Acrylonitrile Butadiene Styrene (ABS): ABS is a tough, impact-resistant material often used in consumer electronics, toys, and automotive interiors.

Polycarbonate (PC): Known for its transparency and high impact resistance, polycarbonate is used in optical lenses, automotive lighting, and electronic housings.

Nylon (PA): Nylon is a strong, wear-resistant material commonly used in mechanical components, gears, and industrial parts.

The choice of material depends on factors such as mechanical requirements, environmental conditions, cost, and the specific application of the part.

Advantages and Applications

Plastic injection molding provides numerous benefits compared to other manufacturing techniques:High Efficiency: Once the mold is created, the production process is highly efficient, allowing for the rapid production of large quantities of parts.

Consistency: Injection molding produces parts with a high degree of consistency, ensuring that each part meets the required specifications.

Design Flexibility: The process allows for complex and intricate part designs, enabling the production of parts with detailed features and tight tolerances.

Material Versatility: A wide range of materials can be used, each offering different properties and benefits.

Due to these advantages, plastic injection molding is used in a wide range of applications, from small consumer products to large automotive components. The process is particularly well-suited for mass production, where large quantities of identical parts are needed.

The choice of material depends on factors such as mechanical requirements, environmental conditions, cost, and the specific application of the part.

Conclusion

In conclusion, plastic injection molding is a highly efficient and versatile manufacturing process that plays a crucial role in producing a wide variety of plastic products. Its ability to produce complex parts with high precision makes it an essential technology in modern manufacturing.