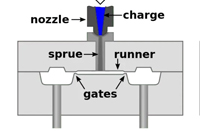

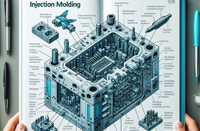

Injection molding stands as a highly prevalent manufacturing method employed for mass-producing plastic components in substantial quantities. The process entails injecting melted material into a mold cavity, where it subsequently cools and solidifies to take on the desired shape. Whether you're working with single or multi-cavity molds, optimizing the injection molding process is crucial for achieving high-quality parts efficiently. Here are some tips for both single and multi-cavity injection molding:

Single Cavity Injection Molding:

1. Design Optimization:

Begin with a well-designed mold. Ensure that the part geometry is suitable for single cavity molding, with uniform wall thickness and adequate draft angles to facilitate easy ejection.

Begin with a well-designed mold. Ensure that the part geometry is suitable for single cavity molding, with uniform wall thickness and adequate draft angles to facilitate easy ejection.2. Material Selection:

Choose the right material for your application based on mechanical properties, temperature resistance, and other requirements. Work closely with material suppliers to select the most appropriate resin for your single cavity mold.

Choose the right material for your application based on mechanical properties, temperature resistance, and other requirements. Work closely with material suppliers to select the most appropriate resin for your single cavity mold.

3. Injection Parameters:

Fine-tune injection parameters such as temperature, pressure, and speed to achieve optimal fill and minimize defects like warping, sink marks, and voids. Conduct thorough process validation to ensure consistency.

Fine-tune injection parameters such as temperature, pressure, and speed to achieve optimal fill and minimize defects like warping, sink marks, and voids. Conduct thorough process validation to ensure consistency.

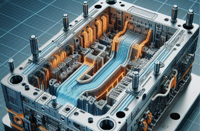

4. Cooling System:

Optimize the cooling system to ensure uniform cooling across the mold cavity. Proper cooling can help prevent distortion and reduce cycle times, improving overall productivity.

Optimize the cooling system to ensure uniform cooling across the mold cavity. Proper cooling can help prevent distortion and reduce cycle times, improving overall productivity.

5. Ejection Mechanism:

Implement an efficient ejection mechanism to safely remove parts from the mold without causing damage. Properly designed ejector pins and ejector systems are essential for successful single cavity molding.

Implement an efficient ejection mechanism to safely remove parts from the mold without causing damage. Properly designed ejector pins and ejector systems are essential for successful single cavity molding.

6. Quality Control:

Implement robust quality control measures to monitor part dimensions, surface finish, and other critical parameters. Regular inspection and testing can help identify issues early and prevent defects.

Implement robust quality control measures to monitor part dimensions, surface finish, and other critical parameters. Regular inspection and testing can help identify issues early and prevent defects.

7. Mold Maintenance:

Schedule regular maintenance for the mold to prevent wear and prolong its lifespan. Clean the mold thoroughly after each production run to remove any residue or contaminants.

Schedule regular maintenance for the mold to prevent wear and prolong its lifespan. Clean the mold thoroughly after each production run to remove any residue or contaminants.

Multi-Cavity Injection Molding:

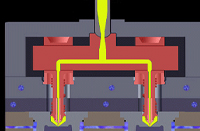

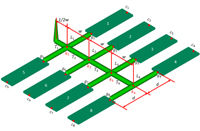

1. Balanced Fill:

Achieve balanced fill across all cavities to ensure uniform part quality. Proper gating and runner design are essential for distributing molten material evenly to each cavity.

Achieve balanced fill across all cavities to ensure uniform part quality. Proper gating and runner design are essential for distributing molten material evenly to each cavity.

2. Runner System Optimization:

Design an efficient runner system to minimize material waste and reduce cycle times. Use techniques such as hot runners or cold runners based on the specific requirements of your multi-cavity mold.

Design an efficient runner system to minimize material waste and reduce cycle times. Use techniques such as hot runners or cold runners based on the specific requirements of your multi-cavity mold.

3. Gate Design:

Optimize gate design to control flow and prevent defects like flow lines and knit lines. Choose gate locations carefully to minimize scrap and maximize part quality.

Optimize gate design to control flow and prevent defects like flow lines and knit lines. Choose gate locations carefully to minimize scrap and maximize part quality.

4. Cavity Arrangement:

Consider the arrangement of cavities within the mold to optimize cooling and minimize the risk of imbalances. Symmetrical layouts can help ensure uniform cooling and reduce cycle variations.

Consider the arrangement of cavities within the mold to optimize cooling and minimize the risk of imbalances. Symmetrical layouts can help ensure uniform cooling and reduce cycle variations.

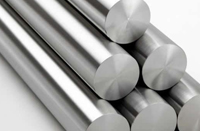

5. Mold Steels:

Select appropriate mold steels with high wear resistance and thermal conductivity for multi-cavity molds. Proper steel selection can help maintain dimensional stability and prolong mold life.

Select appropriate mold steels with high wear resistance and thermal conductivity for multi-cavity molds. Proper steel selection can help maintain dimensional stability and prolong mold life.

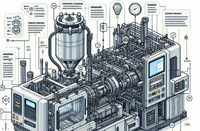

6. Process Monitoring:

Implement real-time process monitoring systems to track key parameters such as temperature, pressure, and fill balance. Continuous monitoring allows for timely adjustments and helps prevent defects.

Implement real-time process monitoring systems to track key parameters such as temperature, pressure, and fill balance. Continuous monitoring allows for timely adjustments and helps prevent defects.

7. Automation:

Explore automation options for multi-cavity molding to improve efficiency and consistency. Automated systems for part removal, inspection, and packaging can streamline production and reduce labor costs.

Explore automation options for multi-cavity molding to improve efficiency and consistency. Automated systems for part removal, inspection, and packaging can streamline production and reduce labor costs.

8. Tooling Considerations:

Invest in high-quality tooling for multi-cavity molds to ensure precise replication of parts. Properly maintained tooling is essential for achieving tight tolerances and consistent quality.

Invest in high-quality tooling for multi-cavity molds to ensure precise replication of parts. Properly maintained tooling is essential for achieving tight tolerances and consistent quality.

9. Simulation Tools:

Use mold flow simulation software to optimize multi-cavity mold designs and predict potential issues before production. Simulation allows for iterative improvements and can help reduce time and cost during tooling development.

Use mold flow simulation software to optimize multi-cavity mold designs and predict potential issues before production. Simulation allows for iterative improvements and can help reduce time and cost during tooling development.

10. Training and Skill Development:

Provide comprehensive training for operators and technicians involved in multi-cavity molding. Proper training ensures that personnel understand the complexities of multi-cavity molds and can troubleshoot effectively.

Provide comprehensive training for operators and technicians involved in multi-cavity molding. Proper training ensures that personnel understand the complexities of multi-cavity molds and can troubleshoot effectively.

Conclusion

whether you're working with single or multi-cavity injection molding, attention to detail and optimization are key to achieving high-quality parts efficiently. By following these tips and continuously refining your processes, you can maximize productivity and minimize defects in injection molding operations.