Injection molding is a pivotal manufacturing process used across industries to produce a vast array of products ranging from automotive parts to medical devices. Central to the efficiency and longevity of this process is the maintenance of injection molds. Mold maintenance is a multifaceted task that requires meticulous attention to detail and adherence to best practices. In this article, we will delve into the key aspects of injection mold maintenance and explore the responsibilities of molders in ensuring optimal performance and longevity of molds.

1. Understanding Injection Mold Maintenance:

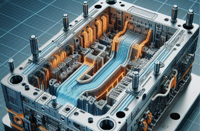

Injection molds are intricate tools comprising various components that facilitate the shaping of molten material into desired forms. Over time, molds are subjected to wear and tear due to repeated use, environmental factors, and the properties of the materials being molded. Mold maintenance encompasses a range of activities aimed at preserving the integrity and functionality of these critical tools.

Injection molds are intricate tools comprising various components that facilitate the shaping of molten material into desired forms. Over time, molds are subjected to wear and tear due to repeated use, environmental factors, and the properties of the materials being molded. Mold maintenance encompasses a range of activities aimed at preserving the integrity and functionality of these critical tools.

2. Regular Cleaning and Inspection:

One of the fundamental aspects of mold maintenance is regular cleaning and inspection. After each production run, molds must be thoroughly cleaned to remove any residual material, debris, or contaminants. Failure to clean molds adequately can lead to defects in subsequent products and compromise the quality of output. Additionally, regular inspection helps identify any signs of wear, damage, or corrosion that may necessitate repairs or replacements.

One of the fundamental aspects of mold maintenance is regular cleaning and inspection. After each production run, molds must be thoroughly cleaned to remove any residual material, debris, or contaminants. Failure to clean molds adequately can lead to defects in subsequent products and compromise the quality of output. Additionally, regular inspection helps identify any signs of wear, damage, or corrosion that may necessitate repairs or replacements.

3. Lubrication and Rust Prevention:

Proper lubrication of mold components is essential for ensuring smooth operation and preventing premature wear. Molders are responsible for applying appropriate lubricants to moving parts and areas prone to friction. Additionally, measures should be taken to prevent rust and corrosion, especially in humid environments or when molds are not in use for extended periods. Rust can impair the functionality of molds and compromise the quality of molded products.

Proper lubrication of mold components is essential for ensuring smooth operation and preventing premature wear. Molders are responsible for applying appropriate lubricants to moving parts and areas prone to friction. Additionally, measures should be taken to prevent rust and corrosion, especially in humid environments or when molds are not in use for extended periods. Rust can impair the functionality of molds and compromise the quality of molded products.

4. Corrective Maintenance and Repairs:

Despite proactive maintenance efforts, injection molds may experience issues that require corrective action. Molders must possess the skills and knowledge to diagnose problems accurately and implement timely repairs. This may involve replacing worn components, repairing damaged surfaces, or addressing issues such as misalignment or excessive flash. Prompt corrective maintenance is crucial for minimizing downtime and preventing production delays.

Despite proactive maintenance efforts, injection molds may experience issues that require corrective action. Molders must possess the skills and knowledge to diagnose problems accurately and implement timely repairs. This may involve replacing worn components, repairing damaged surfaces, or addressing issues such as misalignment or excessive flash. Prompt corrective maintenance is crucial for minimizing downtime and preventing production delays.

5. Temperature and Cooling System Maintenance:

Temperature control is critical in injection molding to ensure proper material flow, fill, and cooling. Mold temperature must be maintained within specified ranges to achieve desired part properties and minimize cycle times. Molders are tasked with monitoring and adjusting temperature settings as needed to optimize production efficiency. Additionally, cooling systems must be inspected regularly to ensure proper functionality and prevent overheating, which can degrade mold performance.

Temperature control is critical in injection molding to ensure proper material flow, fill, and cooling. Mold temperature must be maintained within specified ranges to achieve desired part properties and minimize cycle times. Molders are tasked with monitoring and adjusting temperature settings as needed to optimize production efficiency. Additionally, cooling systems must be inspected regularly to ensure proper functionality and prevent overheating, which can degrade mold performance.

6. Documentation and Record-Keeping:

Effective mold maintenance requires comprehensive documentation and record-keeping practices. Molders should maintain detailed logs of maintenance activities, including cleaning schedules, inspections, lubrication procedures, and any repairs or modifications performed. This information not only serves as a reference for future maintenance tasks but also facilitates traceability and quality assurance processes.

Effective mold maintenance requires comprehensive documentation and record-keeping practices. Molders should maintain detailed logs of maintenance activities, including cleaning schedules, inspections, lubrication procedures, and any repairs or modifications performed. This information not only serves as a reference for future maintenance tasks but also facilitates traceability and quality assurance processes.

7. Training and Skill Development:

Molders play a pivotal role in mold maintenance and must undergo adequate training to perform their responsibilities effectively. Training programs should cover various aspects of mold maintenance, including cleaning techniques, troubleshooting, repair procedures, and safety protocols. Additionally, ongoing skill development is essential to keep abreast of advancements in molding technology and best practices in maintenance.

Molders play a pivotal role in mold maintenance and must undergo adequate training to perform their responsibilities effectively. Training programs should cover various aspects of mold maintenance, including cleaning techniques, troubleshooting, repair procedures, and safety protocols. Additionally, ongoing skill development is essential to keep abreast of advancements in molding technology and best practices in maintenance.

8. Collaboration with Maintenance Technicians:

While molders are primarily responsible for day-to-day maintenance tasks, collaboration with maintenance technicians is essential for addressing complex issues and implementing preventive maintenance strategies. Maintenance technicians possess specialized knowledge and skills in mechanical, electrical, and hydraulic systems, which are invaluable in maintaining and troubleshooting injection molds. By working together, molders and maintenance technicians can ensure the optimal performance and longevity of molds.

While molders are primarily responsible for day-to-day maintenance tasks, collaboration with maintenance technicians is essential for addressing complex issues and implementing preventive maintenance strategies. Maintenance technicians possess specialized knowledge and skills in mechanical, electrical, and hydraulic systems, which are invaluable in maintaining and troubleshooting injection molds. By working together, molders and maintenance technicians can ensure the optimal performance and longevity of molds.

9. Adherence to Safety Protocols:

Safety is paramount in injection molding operations, including mold maintenance activities. Molders must adhere to established safety protocols to mitigate risks associated with working with heavy machinery, hazardous materials, and high temperatures. This includes wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and exercising caution when handling molds and related equipment.

Safety is paramount in injection molding operations, including mold maintenance activities. Molders must adhere to established safety protocols to mitigate risks associated with working with heavy machinery, hazardous materials, and high temperatures. This includes wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and exercising caution when handling molds and related equipment.

10. Continuous Improvement and Optimization:

Finally, mold maintenance is not a one-time task but an ongoing process of continuous improvement and optimization. Molders should actively seek feedback from operators, engineers, and quality control personnel to identify areas for enhancement and implement preventive measures to address recurring issues. By striving for excellence in mold maintenance, manufacturers can achieve higher productivity, lower costs, and superior product quality.

Finally, mold maintenance is not a one-time task but an ongoing process of continuous improvement and optimization. Molders should actively seek feedback from operators, engineers, and quality control personnel to identify areas for enhancement and implement preventive measures to address recurring issues. By striving for excellence in mold maintenance, manufacturers can achieve higher productivity, lower costs, and superior product quality.Conclusion

injection mold maintenance is a critical aspect of ensuring the efficiency, reliability, and longevity of injection molding operations. Molders play a central role in performing routine maintenance tasks, diagnosing and addressing issues, and collaborating with maintenance technicians to optimize mold performance. By adhering to best practices, investing in training and skill development, and fostering a culture of continuous improvement, manufacturers can maximize the return on investment in injection molds and achieve sustainable competitive advantage in the marketplace.