Introduction

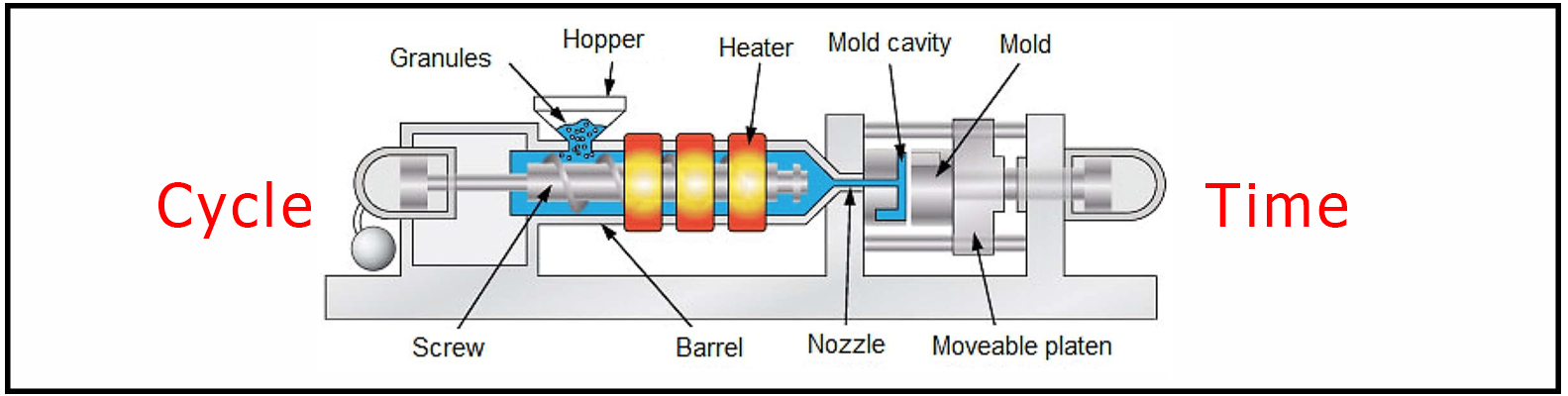

Reducing cycle times in injection molding is crucial for enhancing productivity, improving efficiency, and lowering costs. Here’s a detailed guide on various strategies to achieve this goal:

- 1. Optimize Mold Design:

- - Cooling System: The cooling phase typically consumes a significant portion of the cycle time. Designing cooling channels within the mold efficiently can significantly reduce cooling times. Conformal cooling channels, which align with the part's geometry, ensure uniform cooling and help decrease cycle times.

- - Efficient ejection systems also play a critical role by minimizing the time needed to eject the molded part from the mold. Using multiple ejector pins or air blasts can expedite the ejection process.

- 2. Material Selection:

- - Fast-Cycling Materials: Select materials that cool and solidify quickly. Thermoplastics with lower specific heat capacity and higher thermal conductivity can reduce cooling times.

- - Additives: Incorporate additives that enhance the flow and cooling properties of the material. This can improve mold filling and reduce the overall cycle time.

- 3. Process Parameters Optimization:

- - Injection Speed and Pressure: Adjusting the injection speed and pressure can help fill the mold faster and more efficiently. Finding the optimal balance between speed and pressure is essential to avoid defects while minimizing cycle time.

- - Melt Temperature: Lowering the melt temperature, if the material properties allow, can reduce cooling time. However, this must be done carefully to avoid increasing viscosity and causing filling problems.

- - Cooling Time: Fine-tuning the cooling time by monitoring the mold temperature and part ejection temperature can help in reducing unnecessary cooling phases. Use of real-time temperature monitoring systems can assist in this optimization.

- 4. Advanced Technologies:

- - Hot Runner Systems: Using hot runner systems instead of cold runners can eliminate the need for sprue and runner cooling, reducing cycle times. Hot runners maintain the material in a molten state, ready for injection.

- - Multi-cavity Molds: Employing multi-cavity molds can produce multiple parts per cycle, effectively reducing the cycle time per part.

- - Automation and Robotics: Implementing automation for part handling, such as robots for part removal and packaging, can reduce idle times between cycles.

- 5. Mold Maintenance and Quality:

- - Regular Maintenance: Keeping the mold in optimal condition through regular maintenance can prevent defects and ensure consistent cycle times. Clean molds with well-maintained cooling channels operate more efficiently.

- - Mold Surface Coatings: Applying coatings to mold surfaces can reduce friction and wear, leading to smoother part ejection and shorter cycle times.

- 6. Cycle Time Analysis and Monitoring:

- - Data Collection: Gather detailed data on cycle times and process parameters to pinpoint opportunities for enhancement. Use of monitoring systems can help track performance and detect deviations.

- - Statistical Process Control (SPC): Implement SPC to maintain control over the injection molding process and identify any variations that may affect cycle time.

- - Simulation Software: Use simulation software to analyze and optimize the injection molding process before actual production.

- 7. Operator Training and Skill Development:

- - Training Programs: Ensure operators are well-trained in the latest techniques and technologies for injection molding. Skilled operators can make real-time adjustments to reduce cycle times.

- - Continuous Improvement: Foster a culture of continuous improvement where operators and engineers regularly review processes and suggest improvements.

- 8. Environmental Control:

- - Temperature and Humidity Control: Maintaining a consistent environment in the production area can reduce variations in the molding process, leading to more consistent cycle times.

- - Clean Room Conditions: For high-precision parts, a controlled clean room environment can reduce contamination and defects, leading to more efficient cycles.

- 9. Energy Management:

- - Energy-efficient Machines: Use energy-efficient injection molding machines that offer better control over the process parameters and reduce cycle times.

- - Energy Recovery Systems: Implement systems that recover energy from the cooling process and use it to preheat the material, reducing cycle times and energy consumption.

Conclusion

Reducing cycle times in injection molding requires a comprehensive approach involving mold design optimization, material selection, process parameter adjustments, advanced technologies, and continuous improvement. By implementing these strategies, manufacturers can achieve significant improvements in productivity, efficiency, and cost-effectiveness.