Determining whether you need a prototype is a crucial step in the development of a new product or service. A prototype serves as a preliminary model that allows you to explore ideas, test functionalities, and identify potential issues before full-scale production. Here are some key considerations and steps to help you decide if you need a prototype.

Understanding Prototyping

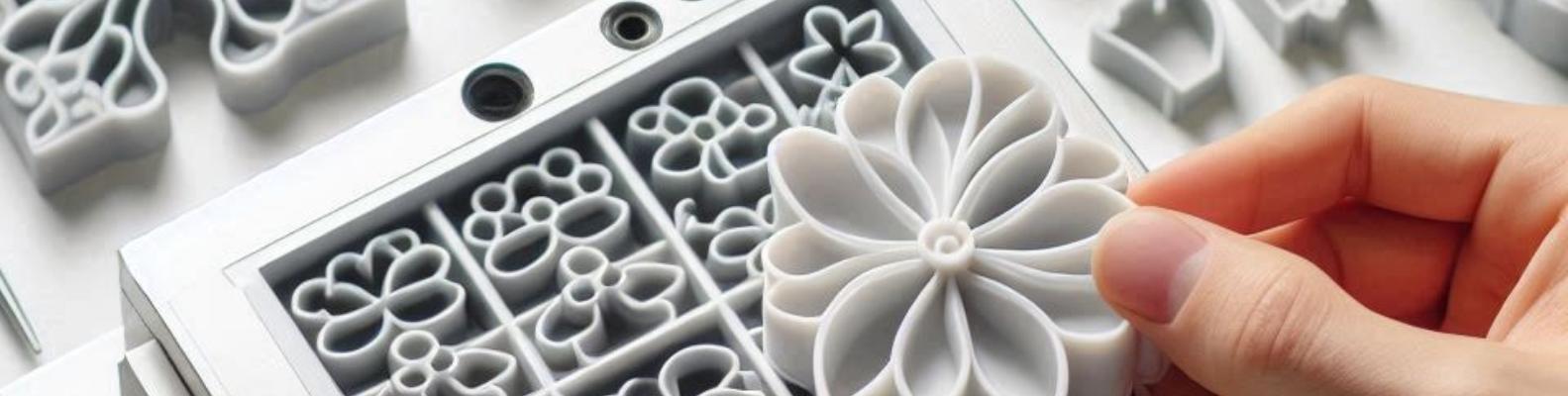

A prototype can take various forms, from a simple sketch or digital mock-up to a fully functional model. The primary purpose is to validate concepts, gather feedback, and refine the design. Prototypes can be used in various stages of product development, including ideation, design, testing, and pre-production.

Reasons to Develop a Prototype

1. Concept Validation: Before investing significant time and resources, it's essential to ensure your idea is viable. A prototype allows you to demonstrate the concept to stakeholders and potential users, providing tangible proof of its feasibility.

2. User Feedback: Engaging with end-users early in the development process can offer invaluable insights. A prototype enables users to interact with the product, offering feedback that can inform design improvements and ensure the final product meets user needs and expectations.

3. Technical Feasibility:Building a prototype helps identify technical challenges and limitations. It allows you to test critical functionalities and determine if your design can be practically implemented with the available technology and materials.

4. Cost Estimation: Prototyping can help estimate the cost of production by providing a clearer understanding of the materials, processes, and time required. This data is essential for budget planning and financial forecasting.

5. Stakeholder Buy-In: A well-crafted prototype can be a powerful tool for securing investment or support from stakeholders. It demonstrates your commitment and provides a concrete example of what the final product will look like and how it will function.

6. Marketing and Presentation: Prototypes can be used in marketing efforts to create buzz and interest in the product before its official launch. They can also serve as effective tools in presentations, trade shows, and pitch meetings.

Types of Prototypes

1. Proof-of-Concept Prototypes: These prototypes focus on demonstrating that the core idea or technology works. They are often rough and basic but crucial for validating the fundamental concept.

2. Functional Prototypes: These models simulate the actual functions and features of the final product. They are more refined than proof-of-concept prototypes and are used for testing and feedback purposes.

3. Visual Prototypes:These prototypes are designed to showcase the appearance and aesthetics of the product. They may not have any functional components but are useful for assessing design and user appeal.

4. User Experience (UX) Prototypes: These prototypes emphasize the user interface and interaction aspects. They are commonly used in software development to test the usability and flow of digital products.

5. Pre-Production Prototypes: These are the final iterations before mass production. They are fully functional and closely resemble the end product, used for final testing and quality assurance.

Steps to Determine the Need for a Prototype

1. Define Your Objectives: Clearly outline what you aim to achieve with the prototype. Are you looking to validate the concept, test functionality, gather user feedback, or secure investment? Defining your objectives will guide the prototyping process and determine the type of prototype you need.

2. Evaluate the Complexity: Assess the complexity of your idea. If the product involves intricate design, new technology, or novel functionality, a prototype will likely be necessary to explore and address these complexities.

3. Identify Risks:Consider the risks associated with your project. High-risk projects, where there is uncertainty about user acceptance, technical feasibility, or market fit, benefit significantly from prototyping as it helps mitigate these risks.

4. Gather Feedback Needs: Determine the importance of early user feedback. If user experience is a critical component of your product, a prototype is essential for collecting actionable insights and making user-centric design decisions.

5. Resource Availability: Consider the resources at your disposal, including time, budget, and expertise. Prototyping requires an investment, so ensure you have the necessary resources to build and test a prototype effectively.

6. Regulatory Requirements: In some industries, prototypes are mandatory to comply with regulatory standards and certifications. Ensure you are aware of any such requirements that may apply to your product.

Benefits of Prototyping

1. Early Error Detection: Identifying and addressing issues early in the development process can save significant time and money. Prototypes help uncover design flaws and technical problems before they become costly to fix.

2. Improved Design: Iterative testing and feedback during prototyping lead to a more refined and user-friendly design. Continuous improvement ensures the final product meets high-quality standards.

3. Enhanced Communication:Prototypes facilitate better communication among team members, stakeholders, and users. They provide a common reference point that everyone can understand and discuss.

4. Market Validation: Prototypes can be used to test market acceptance and gather insights on potential demand, helping to refine marketing strategies and product positioning.

Conclusion

Preventing defects in ABS molded parts requires a comprehensive approach that encompasses optimized process parameters, precise mold design, high-quality materials, and rigorous quality control. By implementing these strategies, manufacturers can produce high-quality ABS parts with minimal defects, ensuring the reliability and performance of their products.

Remember, a well-executed prototype not only saves time and money in the long run but also increases the likelihood of developing a successful product that meets user expectations and stands out in the market.