Plastic injection molding is a widely used manufacturing process for producing plastic parts in large volumes with high precision and repeatability. One critical aspect of this process is the cooling rate, which directly impacts the quality and properties of the final product. In this comprehensive guide, we'll delve into the cooling rate process in plastic injection molding, exploring its significance, influencing factors, and optimization techniques.

Introduction to Plastic Injection Molding:

Plastic injection molding involves injecting molten plastic material into a mold cavity under high pressure, where it solidifies to form the desired shape. The mold is typically made of steel and consists of two halves, the cavity and the core, which define the shape of the final part. After injection, the molten plastic undergoes a cooling phase to solidify and achieve the desired dimensional stability.

Significance of Cooling Rate:

The cooling rate plays a crucial role in determining various properties of the molded part, including its dimensional accuracy, surface finish, mechanical strength, and internal structure. A controlled cooling process is essential to minimize defects such as warping, shrinkage, and sink marks, ensuring the part meets the required specifications.

Factors Influencing Cooling Rate:

1. Material Properties: Different plastic materials have varying thermal conductivities, melt temperatures, and crystallization rates, which affect their cooling behavior. Thermoplastics like ABS, polycarbonate, and polypropylene have different cooling requirements due to their unique characteristics.

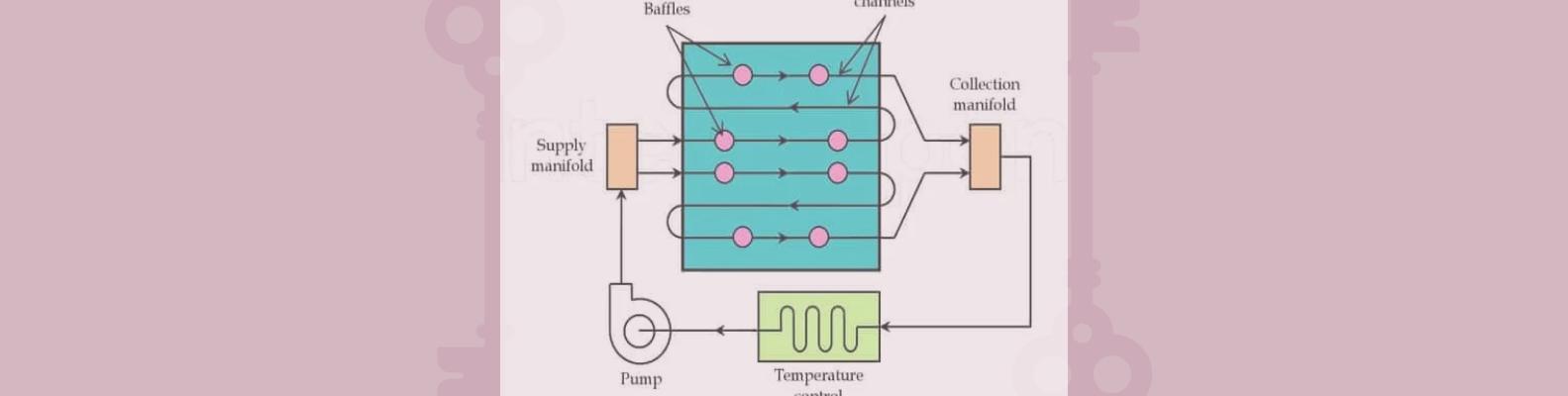

2. Mold Design: The design of the mold, including its geometry, cooling channels, and venting, significantly influences the cooling rate. Efficient cooling channel layouts and uniform heat dissipation help achieve faster and more consistent cooling.

3. Injection Parameters:Factors such as melt temperature, injection speed, pressure, and packing time affect the temperature distribution and cooling rate within the mold cavity. Optimizing these parameters is crucial for achieving the desired part quality and cycle time.

4. Part Geometry: The shape, thickness, and complexity of the part affect the cooling rate and the occurrence of cooling-related defects. Thick sections cool more slowly than thin ones, leading to differential shrinkage and potential warping.

5. Cooling System: The effectiveness of the cooling system, including the type of cooling medium (water or oil), flow rate, and temperature control, directly impacts the cooling rate. Proper cooling system design and maintenance are essential for consistent and efficient cooling.

Cooling Rate Optimization Techniques:

1. Uniform Cooling: Designing the mold with uniform cooling channels and optimizing their layout to ensure consistent heat removal across the entire part surface.

2. Mold Temperature Control: Monitoring and controlling the mold temperature using water or oil circulation systems to achieve the desired cooling rate and minimize thermal variations.

3. Injection Process Optimization:Fine-tuning injection parameters such as melt temperature, injection speed, and packing pressure to optimize the cooling rate and minimize cycle time.

4. Simulation and Analysis: Utilizing computer-aided engineering (CAE) software for mold flow analysis and simulation to predict cooling behavior, identify potential issues, and optimize the cooling system design.

5. Advanced Cooling Technologies: Exploring advanced cooling technologies such as conformal cooling, which involves designing cooling channels following the contours of the part surface for improved heat transfer and reduced cycle time.

Importance of Controlling Cooling Rate:

Controlling the cooling rate is essential for achieving consistent part quality, reducing cycle time, and optimizing production efficiency. A well-controlled cooling process minimizes defects, improves dimensional accuracy, and enhances the mechanical properties of the molded parts, resulting in higher product reliability and customer satisfaction.

Conclusion

The cooling rate process in plastic injection molding is a critical factor that significantly influences part quality, production efficiency, and overall manufacturing costs. By understanding the factors affecting cooling rate and implementing optimization techniques, manufacturers can achieve better control over the molding process, leading to superior quality parts and competitive advantages in the market. Continuous advancements in cooling technology and simulation tools further contribute to the ongoing improvement and innovation in plastic injection molding processes.